Powder Coating for Radiator Restoration

Flawless finish. Dramatic look. Durable, long-lasting color

We get so many calls from around the country asking us: can you help me find a cast-iron radiator restoration company in my neck of the woods?

Why?

Because dry abrasive blasting — paired with expert powder coating — (when they are done right!) are simply the best solution to restoring old radiators.

By the way: we know from experience that doing it right isn’t easy.

We also know you love the warmth your old steam radiators give you on cold wintry days. So we’ve worked hard the last 10 years to develop the very best solution for restoring them.

Why choose powder coating over paint for vintage radiator restoration?

The answer is simple. Water, when mixed with metal makes RUST. Once the original coating on your cast iron radiator is compromised, there will be spots of rust eating away at the metal.

Now these old dinosaurs have layers of peeling of paint. And you’re tired of endless cover-up chores just to make them look halfway decent. It’s exhausting.

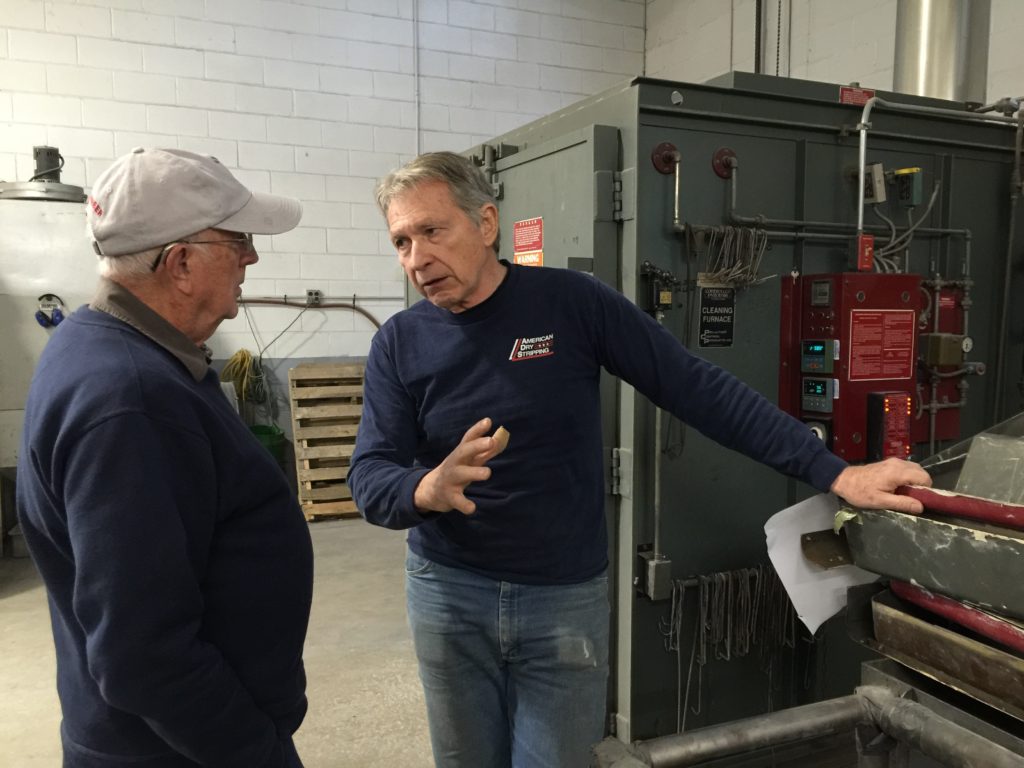

In order to protect these beauties, it’s imperative to get every nook and cranny dry media blasted clean. Our team has the muscle, machinery, and know-how to get it done right.

But it doesn’t stop there. Once the beasts are blasted, they need to be coated properly to ensure water doesn’t invade. When these radiators were coated last time, paint was the only option.

Instead of trying to hide a lumbering eyesore from the guests you invited over for dinner, let us help you restore your radiators to their original distinction.

With the right color and finish, your radiators could blend into the background or intentionally stand out, enhancing your room’s vintage vibe.

The fun part? You get to choose the shade and finish from thousands of durable, long-lasting powder coating colors. Leave the final step of restoring your grubby looking cast iron radiators to our coating team.

Best of all, powder coating is made to withstand radiant heat. Your radiator will look and perform better than new.

When Should You Bring in Your Radiators?

Radiator-restoration season starts with the robin’s first song and wraps up in September! And they pile up in our shop fast. So reach out early to get your beauties blasted and ready before the leaves fly!

Don’t let pool time distract you! Call us to schedule pick up and delivery for your radiators’ summer glow-up. You can have them stripped of all that old paint and corrosion and looking gorgeous just in time for sweater weather.

We specialize in cast iron radiator sandblasting and powder coating.

Using our expertise in surface preparation, we remove rust and corrosion in order to create flawless, even finishes. Our mission is to provide the best cast iron radiator restoration services in the North East.

What to Expect with Our Process of Restoring Cast Iron Radiators

- Excellent Results. The best cast iron radiator sandblasting and powder coating services in the Northeast.

- High-quality surface preparation and finish workmanship

- Customer service excellence – every step of the way

- Competitive Pricing

- Unparalleled Expertise

Discover the reasons we are renowned as the most recommended and best radiator sandblasting and powder coating service in CT, NY, NJ, MA and RI. Don’t just take our word for it. See examples in our portfolio, or read some of our customer testimonials here.

Let’s Get Started!

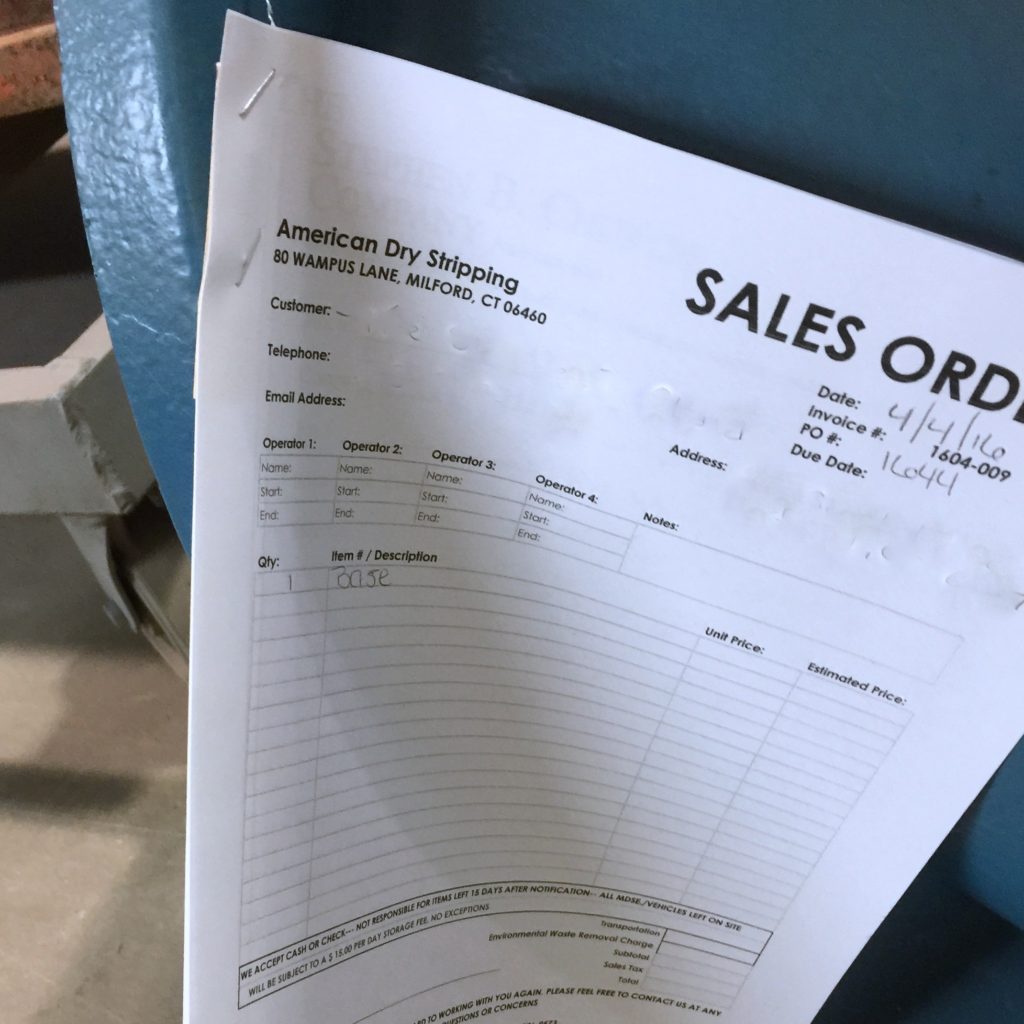

What do you we need? A photo of your item(s) may be helpful when providing a quote. Please tell us how many items, when you need them done, and if you will be dropping them off in Milford, CT or if need pick-up and delivery services.

- Contact Us using our form. We will reply within 1 business day.

- Call us at (203) 876-9876 to speak to someone

- M-Th 8:00 AM – 4:30 PM. Friday 8:00 AM – 3:30 PM. Saturday 8:00 AM – 11:30 AM.

Radiator Sandblasting and Powder Coating Service Locations

All radiators are serviced in our Milford, CT Sandblasting and Powder Coating at

80 Wampus Lane #13, Milford, CT 06460

Pick-up and Delivery Services in areas listed below

- Hartford, Bridgeport, Stamford, Waterbury, Danbury, Norwalk

- Hartford County, Tolland County, New Haven County, New London County, Middlesex County, Litchfield County, Windham County, Fairfield County

We serve New York with Sandblasting and Powder Coating in the following areas:

- New York City

- Long Island

- Westchester County

- Nassau County

- Suffolk County

- Rockland County

We serve Massachusetts with Sandblasting and Powder Coating in the following areas:

- Boston

- Worcester

- Springfield

- Lowell

- Cambridge

- New Bedford

We serve Rhode Island with Sandblasting and Powder Coating in the following areas:

- Providence

- Warwick

- Cranston

- Pawtucket

- Woonsocket

- Newport

Powder Coating for Radiator Restoration Read More »

to see our powdering coating portfolios!

to see our powdering coating portfolios!

Working with these chemicals on your own means investing in protective gear:

Working with these chemicals on your own means investing in protective gear: