Should I Restore that Classic Car, or Buy a Restoration?

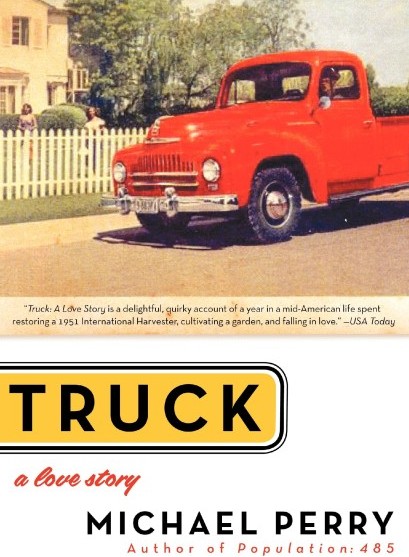

If you are dreaming about joining the summer cruises in the classic car of your dreams, you have two choices: restore a classic car or buy one.

American Dry Stripping™ & Xtreme Coatings helps people with car restoration services. We are based in Milford, Connecticut and serve customers in metropolitan New York and surrounding counties, Long Island, Rhode Island, and Massachusetts. Contact us to learn more.

Click the link below

We offer a pick-up and delivery service.

If you’ve been thinking about restoring a classic car yourself, take a moment. Finally owning and driving a restored classic car is like reuniting the with that gorgeous high school girlfriend that got away. And she hasn’t aged a bit!

Autoweek shared four excellent thoughts to ponder when you are considering a DIY restoration. Not the least of which is cost: over time, you will more than likely spend MORE restoring the car yourself than you would if bought a fully restored car.

Done properly, restoring that six-cylinder ’Stang will cost almost as much as redoing a GT 350. In number terms, think about $100,000 in a car that on a good day might get $25,000.

Still there are at least as many good reasons to restore a classic car which outweigh the bottom line.

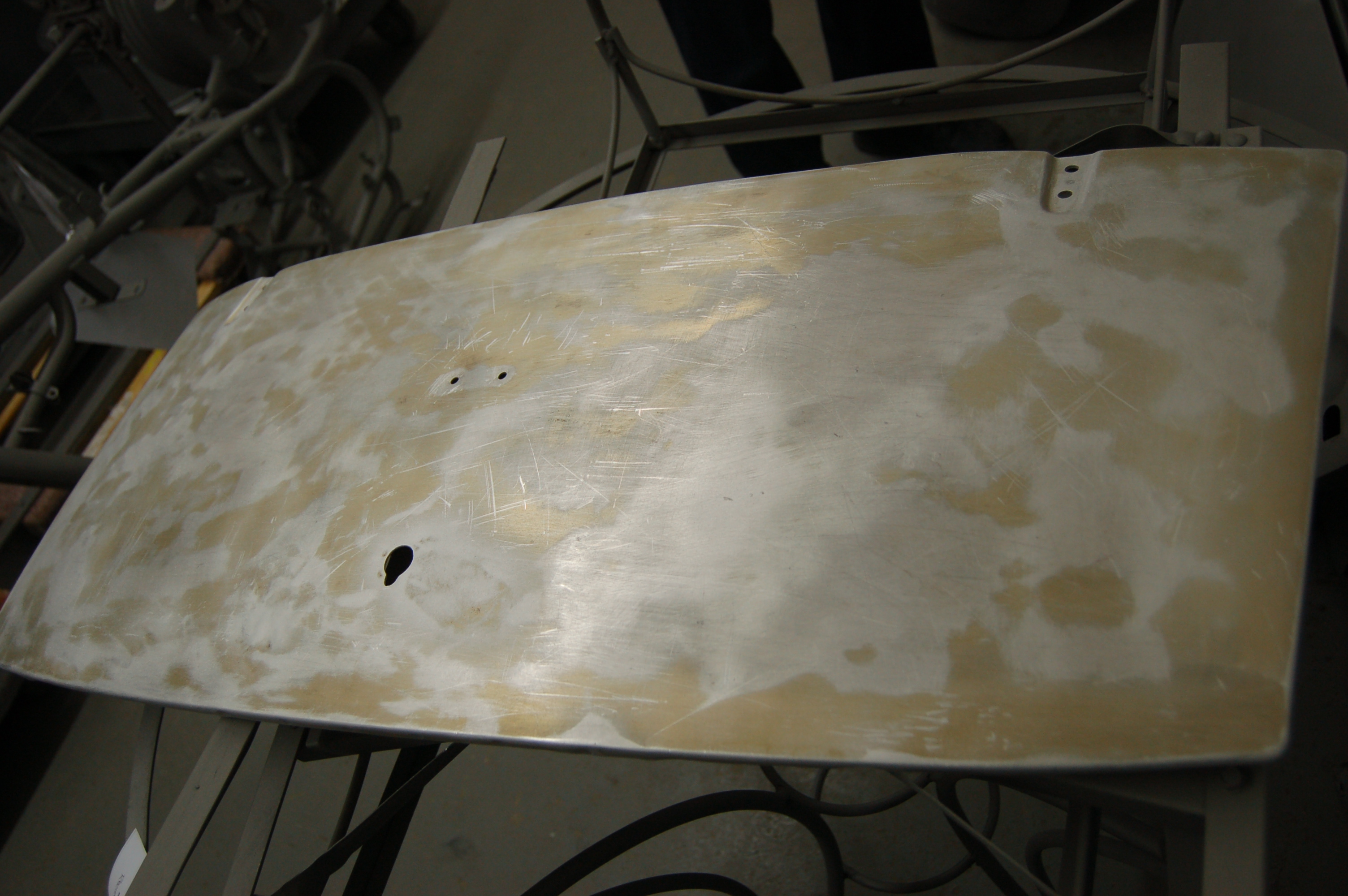

Not the least of which is the satisfaction of driving a beauty you saved from the rust heap.

If you have questions about how professional dry abrasive blasting gets your classic car restoration project done right, contact us today. We are the experts.

American Dry Stripping™ & Xtreme Coatings helps people with car restoration services. We are based in Milford, Connecticut and serve customers in metropolitan New York and surrounding counties, Long Island, Rhode Island, and Massachusetts. Contact us to learn more.

- Sandblasting and media blasting services

- Click here -> (Cars) to see our portfolio!

We offer a pick-up and delivery service.

Should I Restore that Classic Car, or Buy a Restoration? Read More »

If you think

If you think