How We Approach Industrial Abrasive Blasting

For most of our abrasive blasting clients, we work in limited scope, size, weight or number of items for blasting and powder coat turnaround.

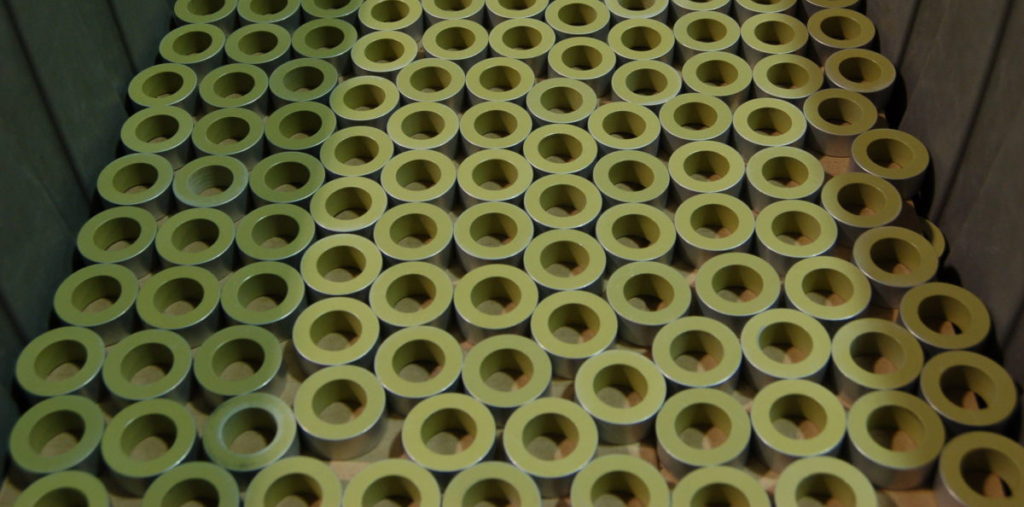

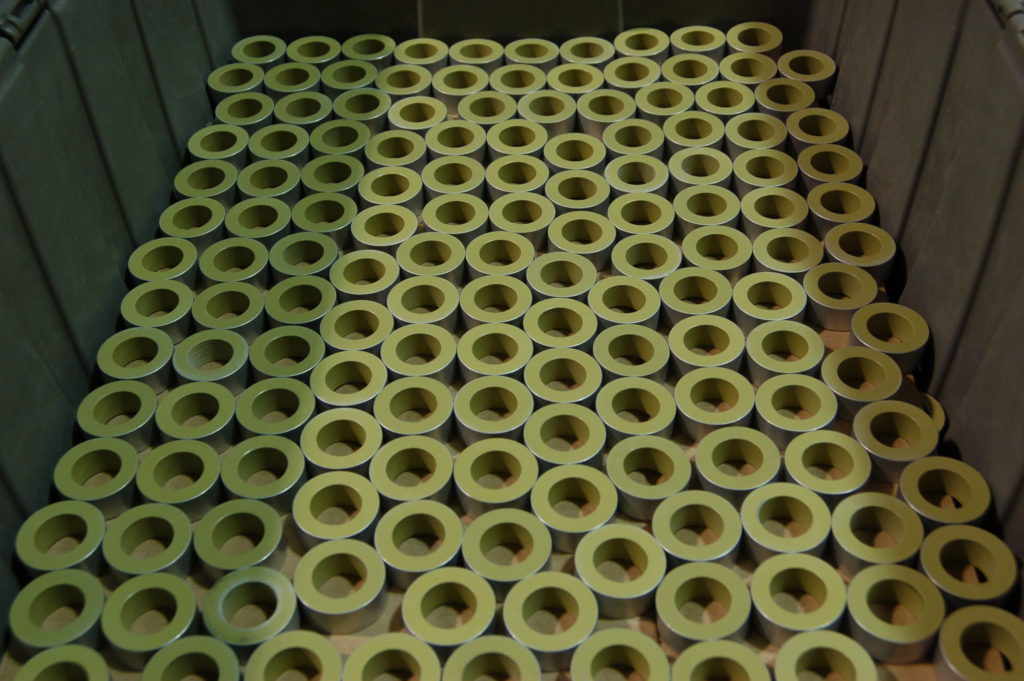

For our industrial abrasive blasting clients, we often manage bulk quantities of items to blast. These items can be very small to oversized in extreme weights and measurements. This requires a precise logistical workflow — from pick-up and blasting to wrapping, packing and delivery.

American Dry Stripping™ & Xtreme Coatings helps people with all of their industrial sandblasting and media blasting needs. We are based in Milford, Connecticut and serve customers in metropolitan New York and surrounding counties, Rhode Island, and Massachusetts. Contact us to learn more.

Click the link below ⬇ to see our industrial portfolio!

We offer a pick-up and delivery service.

At American Dry Stripping, we have 30-plus years experience serving industrial clients in the Northeast.

From heavy grit and high-pressure for the tough jobs to ultra-fine bead for the delicate surfaces, we evaluate and perform each industrial abrasive blasting task with care and precision.

Industrial abrasive blasting at American Dry Stripping:

- Completed hundreds of projects successfully, large and small

- Trained, certified blasters & technicians

- Oversized blast booths for large, industrial equipment

- Ingersoll-Rand air dryer with oil-water separators to remove all particulate matter, delivering absolute clean, dry air to the blast hose nozzles

- Surface profiling and surface preparation for paint and powder coating

- Experience cleaning up heat treatment and weld marks

- Experience removing coatings on new and used parts in varying alloys, metals and other surfaces

- EPA-approved burn-off oven

- In-house powder coating services for seamless finishing

- Humidity and temperature controlled holding room for completed work

- 24-foot climate-controlled, enclosed trailer for pick-up and delivery

At American Dry Stripping we follow specifications set by the Society for Protecting Coatings (SSPC) and NACE, The Worldwide Corrosion Authority for industrial abrasive blasting and stripping work projects. We employ stringent internal quality control processes that meet our industrial abrasive blasting customers’ requirements.

American Dry Stripping™ & Xtreme Coatings helps people with all of their industrial sandblasting and media blasting needs. We are based in Milford, Connecticut and serve customers in metropolitan New York and surrounding counties, Rhode Island, and Massachusetts. Contact us to learn more.

We offer a pick-up and delivery service.

How We Approach Industrial Abrasive Blasting Read More »