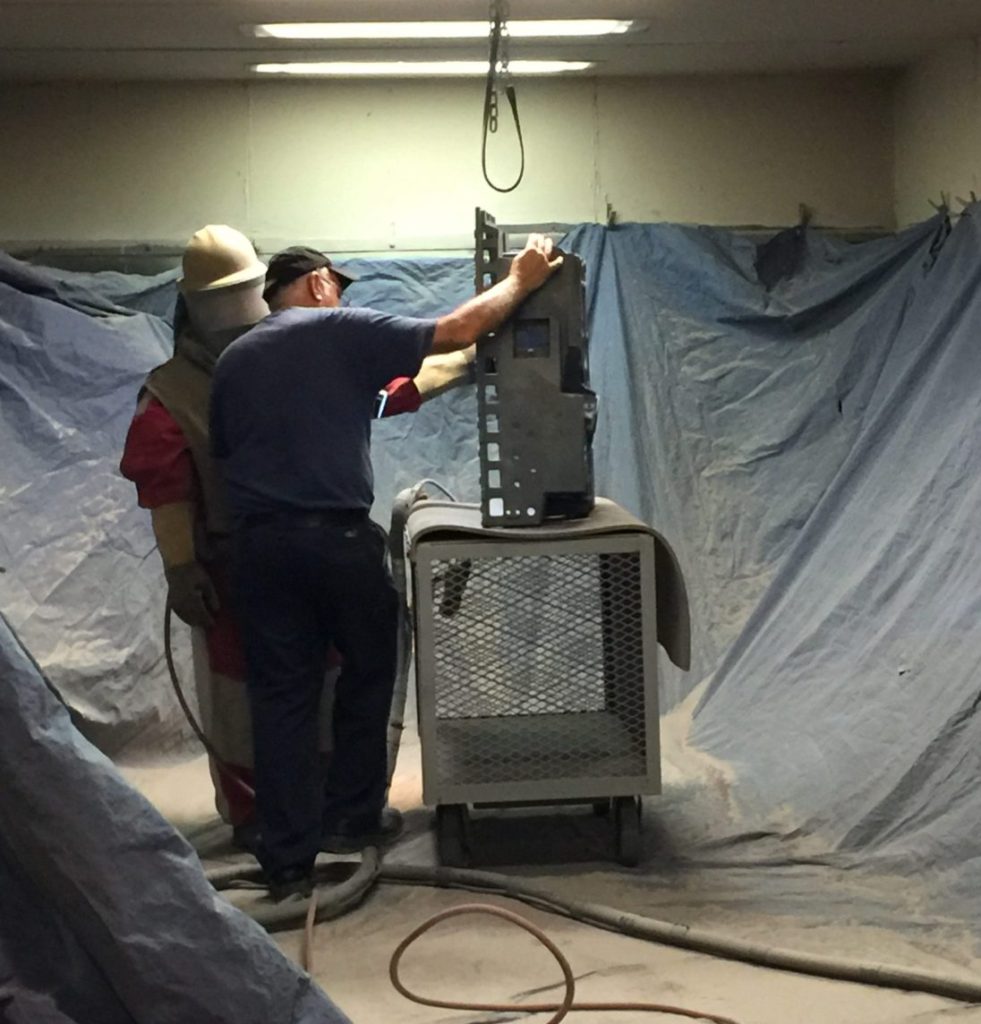

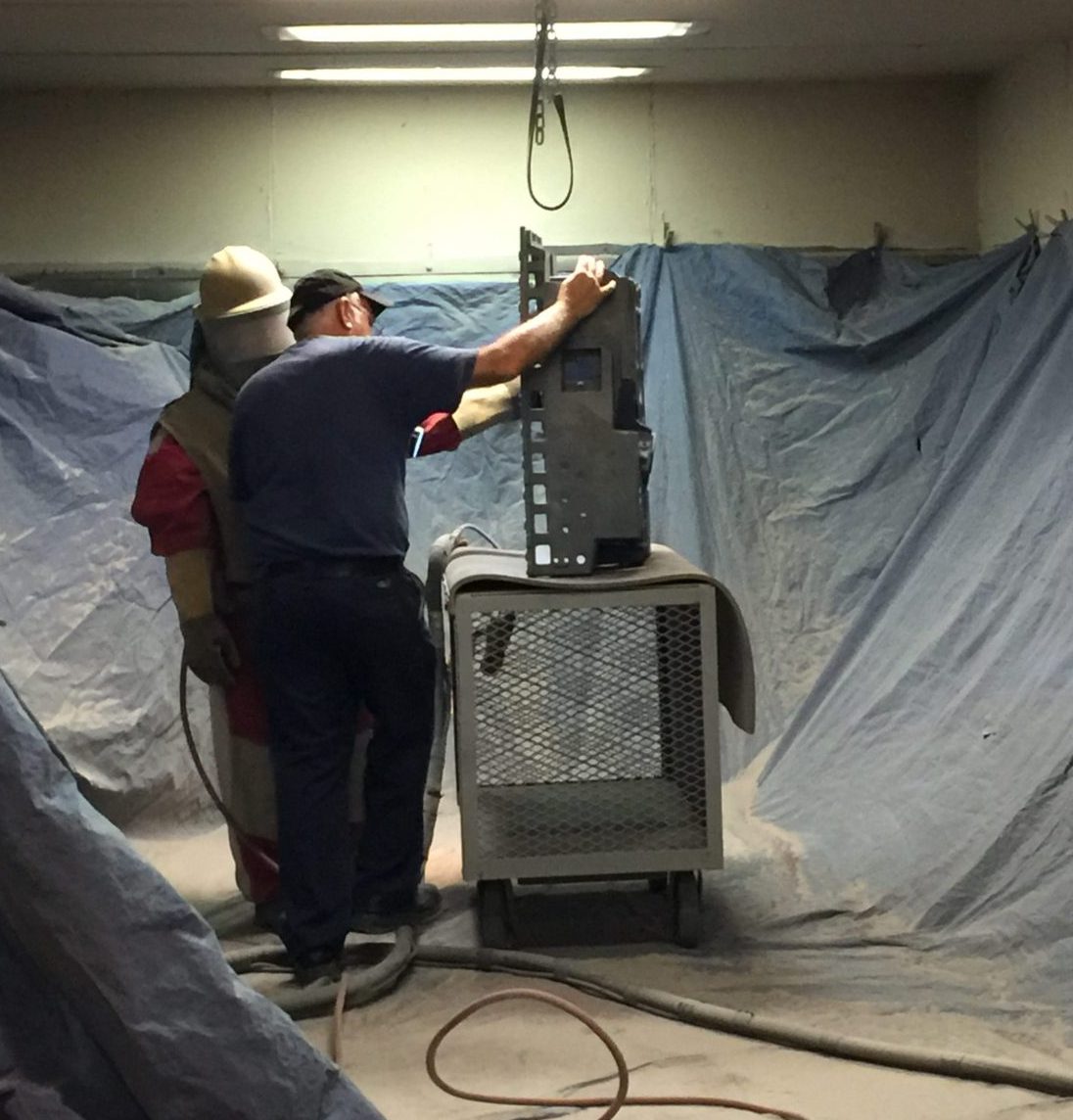

Most anyone working in the metals industry today is aware of the many benefits derived from abrasive media blasting a metal component.

American Dry Stripping™ & Xtreme Coatings helps people with sandblasting and media blasting service needs. We are based in Milford, Connecticut and serve customers in metropolitan New York and surrounding counties, Long Island, Rhode Island, and Massachusetts. Contact us to learn more.

Click the link below

We offer a pick-up and delivery service.

This process, also referred to as sandblasting, is recognized as one of the best methods to “strip” or remove contaminants like rust (oxide), corrosion, fabrication imperfections and paint or powder coat from the surface of metal materials.

This methodology can also be effectively applied to other hard surfaces like fiberglass and carbon fiber.

Surface Prep and Profiling

Another purpose for the abrasive blasting process is to effectively add an adhesion profile or etch to a metal surface. Surface profiling or magnitude of roughness, is determined by the requirements of the customer’s application for the material.

Profiling manipulates coefficient of friction for a particular surface that results in improved adhesion properties for a subsequent surface finish such as paint or powder coat. Thus, abrasive media blasting is one of the most cost effective, efficient ways to prepare a hard surfaced material for surface finishing work either by removing fabrication imperfections, stripping rust or attaining a desired profile.

Removing Rust and Corrosion

Removing rust from metals is in most cases important because rust can severely damage or erode and degrade surfaces to the point where the metal, especially as it pertains to machinery, is no longer structurally useful and in fact in some cases dangerous.

Abrasive media blasting strips the existing oxidation leaving an exposed metal surface. Once the decision is made to blast clean a metal surface it is critical to have a plan for protecting the exposed metal because once surface contaminants are removed rust bare, raw metal is once again exposed to the oxidation process. Time, temperature and humidity become your enemies in the battle to preserve the newly exposed metals. Properly and completely removing rust from a metal is perhaps the single most important step we at American Dry Stripping can help you take to ensure longevity of your equipment or component parts and they are restored to their most optimal condition.

The benefits of abrasive media blasting at American Dry Stripping

Years of Expertise Equals Quality Workmanship

Not all abrasive blasting companies are equal.

Our team brings years of professional experience to each job entrusted to us. They have the expertise to strip and blast clean any type of metal or fiberglass hard surface parts.

You can be confident:

- component parts are thoroughly prepared per work order requirements

- no damage to components

- the safest methods of stripping available

- precise, optimal project outcomes.

Our media blasting products include versatile and “green” materials such as plastic, glass bead or other types of environmentally friendly media. It is imperative to know the optimum size and type of grit (media) to utilize and the time, angle, distance and pressure to deliver to the surface to insure the original metal, alloy or fiberglass surface is not damaged yet achieve optimal surface, blast & strip cleaning.

Time Efficiency

There is a financial advantage to abrasive media blasting. By using these different methods of blasting and media types, we can complete jobs effectively and in the most cost efficient manner.

In the past, when steel or other metals needed cleaning, it took days of scrubbing and soaking in harsh chemicals. Now, thanks to state-of-the-art abrasive blasting techniques, these jobs can be completed in hours instead of days, saving money, time, and labor.

American Dry Stripping

Whether you are an industrial organization or a car enthusiast, economics and time are significant considerations for any job. Our experts can counsel you on balancing time and budgets, especially important when it comes to automotive restorations, and make recommendations for optimal outcomes. For example, how a car arrives at ADS is a factor in cost. Frame-off or frame-on, rolling frames, complete car bodies, or individual parts is no problem for our professionals and we are happy to work with you to fit your budget and timeline.

Even if you are passionate and dedicated to restoring classic cars and love DIY projects, there comes a time when choosing a professional abrasive blasting and stripping company is the best choice for the outcome of your project. While blasting equipment and other tools are readily available, the process is time consuming, frustrating and usually results in damage to metal or fiberglass and a less than perfect stripping outcome if completed as a DIY project. Not only do we provide a clean and efficient blasting job, but also you will not have to worry about any airborne dust, environmental issues or the hassle associated with cleanup. Industrial abrasive media blasting and stripping is a better choice for your automotive restoration project, so bring yours to American Dry Stripping today.

American Dry Stripping™ & Xtreme Coatings helps people with sandblasting and media blasting service needs. We are based in Milford, Connecticut and serve customers in metropolitan New York and surrounding counties, Long Island, Rhode Island, and Massachusetts. Contact us to learn more.

We offer a pick-up and delivery service.